Innovative Dutch start-up shapewave® sets an inflatable revolution in the sailing/boating sector

by shapewave 9 Nov 2023 21:26 NZDT

15-17 November 2023

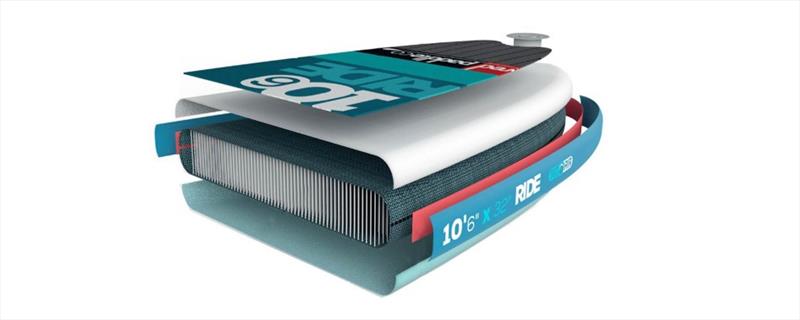

Red Paddle © shapewave

shapewave® innovation is set to revolutionise inflatable product applications in the marine leisure sector.

Imagine being able to 3D shape inflatable marine sport and leisure products exactly the way you want without complex tooling or high start-up costs, and you will realise the possibilities are endless.

Current inflatable product manufacturing processes utilise a technique called drop stitching to connect two pieces of polyester fabric together binding them in place with a plethora of fine polyester threads. When air is added the threads are pulled tight and a 100% flat surface is achieved (as seen in the image from Red Paddle above).

shapewave has developed a revolutionary technique whereby, instead of stitching the internal structure, a series of ribbons are welded internally to the outer skin of the product.

Using CAD and shapewave's proprietary WAM (Web Allocation Module) software, a designer has greater control over the placement and distance of the ribbons between the outer layers meaning shape and form can be integrated into the design.

Enhanced inflatable board design

Utilising shapewave's manufacturing technology, inflatable boards can be built at less than half the weight of that of drop stitch manufactured inflatable boards. The technique can produce complex convex and concave curved inflatable structures and offers significant weight savings in addition to enhanced performance characteristics. Also, thanks to pliable and lightweight membrane material, they will pack down compactly.

Board shapers are no longer trapped by the limitations of drop stitching and can incorporate smooth rockers, asymmetric sections, rails, internal beams; the future of their board shape designing dreams are freed!

Andrew McPherson (Co-Founder GC32 Racing Class) recognises that "In the watersports market there are numerous exciting applications for shapewave, from airfoils for kites and wings to SUP boards and even RIB hulls."

Revolutionising wingsails

shapewave wingsails provide an economical, safe, and rollable alternative to cumbersome and unsafe sail constructions used in modern sail racing. Our manufacturing process can create an aerodynamic wingsail around internal objects such as inflatable structural beams and prevent the outer membranes from bulging outwards on unsupported areas.

Pieterjan Dwarshuis (CEO of DNA Performance Sailing as well as Holland Composites) is excited about the many possibilities of the shapewave technology. "I am enthusiastically looking forward to build the first shapewave powered DNA Performance wingsail!"

Handheld wings

Built with shapewave welding technology, handheld wings, such as those used in Foil Boarding, can finally have an optimised aerodynamic profile and an enhanced stiffness but retain the same construction weight as existing Leading Edge Inflated (LEI) wing constructions.

Other examples of where shapewave is applicable in the marine leisure industry include rib hulls, canoes, kayaks, towables, surf boards, SUP Boards, foil boards, biminis, lifebuoys, awnings, dinghies, cushioning, rescue products and rafts.

METSTRADE is the world's largest trade exhibition for equipment, materials, and systems for the global leisure marine industry and will run from 15-17 November 2023 at the RAI Convention Centre in Amsterdam, celebrating its 35th anniversary.

shapewave will be there at stand 07.2201 in the Start-Up Pavillion in Hall 7 to answer any questions you have about our proprietary shapewave tool chain and engineering services and give you the opportunity to hold a recently manufactured wing in your own hands. You will also see first hand how the internals of the wing are constructed and be updated on the build and testing progress of our first Wavemaker01 fully automated welding robot.

shapewave was one of only 15 innovative start-ups to be carefully selected to exhibit in the METSTRADE Start-Up Pavillion and are being recognised for our commitment to sustainability, environmental preservation, and technological ingenuity.

shapewave's journey has only just begun, and we realise that while the above examples are very recognisable, many more applications in alternative markets will cross our path.

Maybe you have some ideas of your own. Come and discuss them with us at stand 07.2201 in the Start-Up Pavilion in Hall 7.

We are looking forward to meeting you, explaining our technology, sharing ideas and discussing potential opportunities.

For more information about METSTRADE 2023 please visit www.metstrade.com/exhibiting/start-up-pavilion

For more information about shapewave please visit www.shapewave.eu